Prefabrication

Chapel Electric’s prefabrication shop contains the latest fabrication tools and specialty equipment and is supported by our in-house virtual construction designers and BIM experts. We apply our own Underwriters Laboratories (UL) listing tag on all of our assemblies, which speaks to the quality of our process, products, and engineering. UL is a globally recognized, independent safety science organization, and we undergo thorough quarterly quality inspections to validate our shop’s listing.

Chapel Electric’s prefabrication shop contains the latest fabrication tools and specialty equipment and is supported by our in-house virtual construction designers and BIM experts. We apply our own Underwriters Laboratories (UL) listing tag on all of our assemblies, which speaks to the quality of our process, products, and engineering. UL is a globally recognized, independent safety science organization, and we undergo thorough quarterly quality inspections to validate our shop’s listing.

A majority of the production is done in a controlled environment specifically designed to manufacture and assemble the individual prefabricated components. The controlled shop environment allows us to include additional quality checks and perform more comprehensive reviews than possible on a job site. It also helps improve the safety of the entire project by limiting variables and keeping field worksites tidy and free of clutter.

There are many benefits to using prefabrication, sometimes called modular construction, on electrical projects:

- Improved quality control

- Not dependent on local skilled workforce

- Optimized workflow for increased production

- Cleaner job sites

- Improved safety

- Customized system and component design

- Streamlined installation and expedited schedules

- Greater certainty on both build times and costs

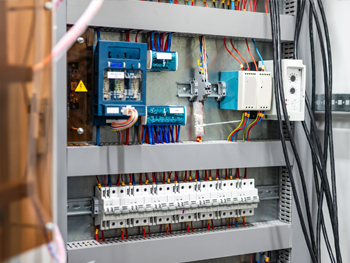

Our Prefabrication Offerings:

- Conduit and raceway support systems

- Equipment- and device-flexible connection assemblies

- Panelboard modifications with conduits

- Pre-punched boxes and brackets

- Wired and non-wired device assemblies

- Light fixture preparation

- Large or small conduit bending

- Temporary lighting or power

- Branch circuit home run wiring bundles

- Conduit sleeves

- Lighting controls

- In-wall assemblies

- Underground conduit systems

- Threading rigid conduits

- Spooling of feeders and branch circuits